Products >> Steel Pipes/Tubes/Chromed Bars >> Hydraulic cylinder tubing

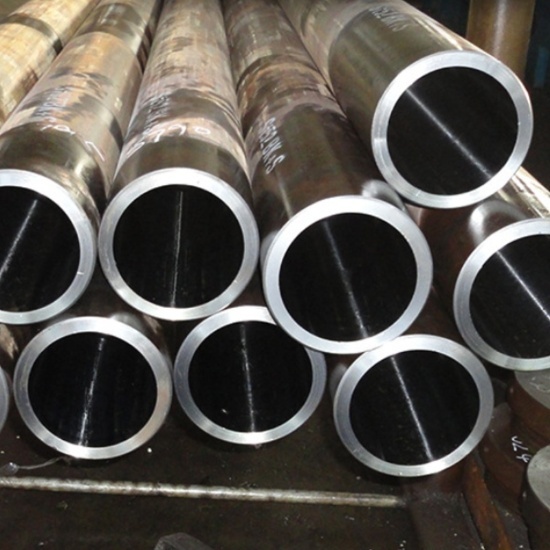

Hydraulic Seamless Pipe

- Product No.:2024102812614

Hydraulic Seamless Pipe

Hydraulic systems play a crucial role in a wide range of industries, from construction and manufacturing to oil and gas exploration. At the core of these systems is the hydraulic seamless pipe, a specialized tube designed to handle high pressures and provide smooth fluid transfer. In this article, we’ll explore what makes hydraulic seamless pipes unique, their manufacturing process, applications, and why they are essential for maintaining system integrity in high-pressure environments.

What is a Hydraulic Seamless Pipe?

A hydraulic seamless pipe is a type of steel tubing specifically designed to withstand the high-pressure demands of hydraulic systems. Unlike welded pipes, which have a seam that can become a weak point under stress, seamless pipes are produced without any welding, making them stronger and more reliable. Seamless pipes are manufactured from a single piece of steel, which is stretched out and pierced to form a hollow tube. This results in a uniform, seamless structure that is highly resistant to pressure and fatigue.

Key Characteristics of Hydraulic Seamless Pipes

- Seamless construction: No welded joints, making them stronger and more resistant to pressure.

- High-pressure resistance: Designed to handle intense hydraulic pressures without deforming or failing.

- Smooth interior: Ensures the efficient flow of hydraulic fluids, reducing friction and wear.

- Corrosion resistance: Often treated or coated to resist corrosion from hydraulic fluids and environmental conditions.

- Precision dimensions: Manufactured to exact specifications to ensure a perfect fit in hydraulic systems.

Manufacturing Process of Hydraulic Seamless Pipes

The production of hydraulic seamless pipes involves several key steps to ensure they meet strict quality and performance standards.

1. Material Selection

The first step is selecting the right raw material, typically high-quality carbon steel or alloy steel. The material must have excellent mechanical properties to withstand the rigors of high-pressure hydraulic systems.

2. Hot Forming

The raw steel is heated to a high temperature and then passed through a series of rollers to form a cylindrical shape. This process, known as hot forming, stretches the steel into a long tube. The absence of welding in this process ensures the pipe remains seamless and strong.

3. Piercing

After the steel is formed into a cylindrical shape, it is pierced with a specialized tool to create a hollow tube. This step is critical in ensuring the pipe is truly seamless.

4. Cold Drawing

To achieve the precise dimensions required for hydraulic systems, the tube is often cold-drawn after the piercing process. Cold drawing involves pulling the tube through a die at room temperature, refining its dimensions and improving its strength and surface finish.

5. Heat Treatment

To enhance the mechanical properties of the seamless pipe, heat treatment processes like annealing or normalizing are used. These treatments help relieve stress, increase toughness, and improve overall performance.

6. Testing and Inspection

Each hydraulic seamless pipe undergoes rigorous testing to ensure it meets the required pressure ratings and dimensional tolerances. Tests include hydraulic pressure testing, non-destructive testing (NDT), and visual inspection to identify any potential defects.

Applications of Hydraulic Seamless Pipes

Due to their ability to withstand high pressures, hydraulic seamless pipes are used in a variety of industries and applications where reliable fluid transfer is essential. Below are some of the key sectors where these pipes play a vital role:

1. Construction and Heavy Equipment

Hydraulic systems in construction equipment like excavators, bulldozers, and cranes rely on seamless pipes to transfer hydraulic fluid efficiently. The high-pressure resistance of these pipes is critical for ensuring the equipment operates safely and effectively.

2. Automotive Industry

In the automotive sector, hydraulic systems are used for various functions, including power steering and brake systems. Hydraulic seamless pipes ensure smooth fluid transfer and consistent pressure, which is essential for vehicle safety.

3. Oil and Gas

In the oil and gas industry, hydraulic systems are used in drilling rigs, pipelines, and offshore platforms. The harsh environmental conditions and high pressures in this industry make seamless pipes the preferred choice for ensuring reliability and preventing leaks.

4. Aerospace

The aerospace industry demands precision and reliability, especially in hydraulic systems used for landing gear, flight controls, and other critical components. Hydraulic seamless pipes provide the necessary strength and durability for these high-stakes applications.

5. Manufacturing

Hydraulic machinery in manufacturing plants often relies on high-pressure systems to operate presses, lifts, and other heavy-duty equipment. Hydraulic seamless pipes are essential for maintaining system efficiency and minimizing downtime.

Benefits of Using Hydraulic Seamless Pipes

1. Superior Strength

The seamless construction of these pipes eliminates the risk of weak points, making them much stronger than welded pipes. This strength is critical in high-pressure applications where failure is not an option.

2. High Corrosion Resistance

Hydraulic seamless pipes are often coated or treated to resist corrosion from hydraulic fluids and harsh environmental conditions. This increases their lifespan and reduces maintenance costs.

3. Smooth Flow of Fluids

The smooth interior surface of seamless pipes allows for the efficient flow of hydraulic fluids, minimizing friction and reducing wear on the system. This helps maintain consistent pressure and improves overall system performance.

4. Precision Fit

Seamless pipes are manufactured to precise dimensions, ensuring a perfect fit within hydraulic systems. This reduces the risk of leaks and enhances system efficiency.

5. Cost-Effective in the Long Run

While seamless pipes may have a higher upfront cost compared to welded pipes, their superior durability and lower maintenance requirements make them a cost-effective choice in the long term.

Why Choose XUDSTEEL for Hydraulic Seamless Pipes?

XUDSTEEL is a trusted leader in the manufacturing of hydraulic seamless pipes, known for delivering premium-quality products that meet the stringent demands of high-pressure systems. We use advanced production techniques, ensuring precision, durability, and corrosion resistance. XUDSTEEL’s pipes are engineered for long-term performance, helping businesses reduce maintenance costs and improve operational efficiency. With customized solutions tailored to industry-specific needs, we provide seamless pipes that guarantee reliability and safety.

Hydraulic seamless pipes are essential to modern hydraulic systems, offering the strength, durability, and precision required for high-pressure applications. Across industries such as construction, automotive, oil and gas, and aerospace, these pipes ensure reliable and efficient system performance. Choosing high-quality hydraulic seamless pipes not only boosts system efficiency but also minimizes downtime and maintenance costs, making them a valuable investment for any business that relies on hydraulic power.

By recognizing the critical role and advantages of hydraulic seamless pipes and choosing XUDSTEEL as your supplier, companies can make well-informed decisions, ensuring enhanced reliability, longevity, and cost-effectiveness in their hydraulic systems.

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry