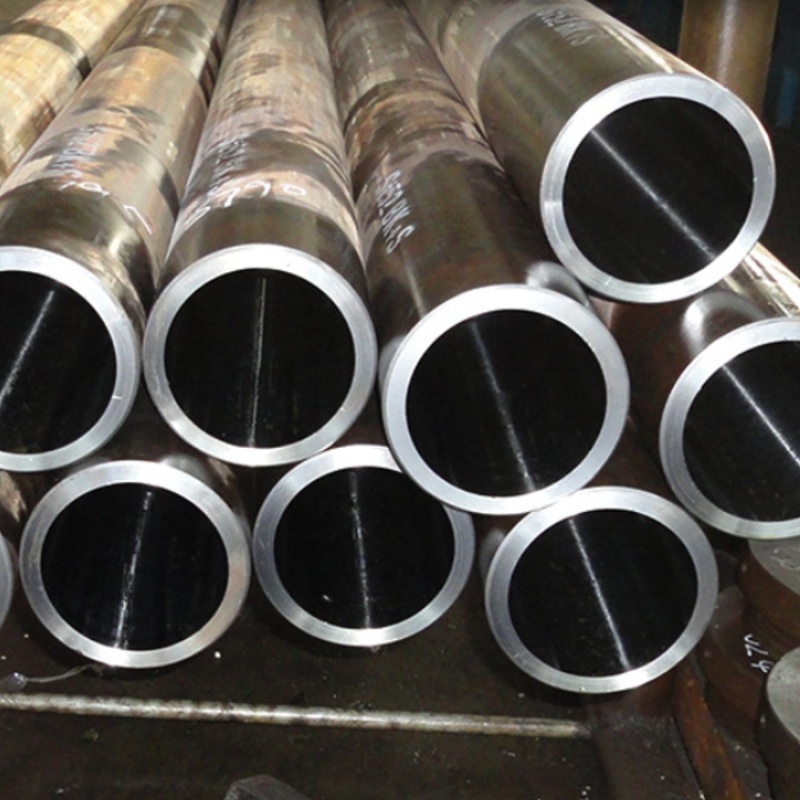

DIN 2391 Precision cold drawn seamless steel tube

DIN 2391 Precision cold drawn seamless steel tube

DIN 2391 applies to seamless precision steel tubes and in compliance with ISO/DIN 3304, those tube dimensions have been selected from the range of manufacture dimensions which are mainly used as design elements.

Notes: DIN 2391 Pipe Seamless Precision Steel Tubes

1. Steel grades: St 35, St 45, St 52

2. Length up to 9 m.

3. Outside Diameter : 10 - 260 mm

4. Wall Thickness: 0,5 - 25 mm

5. Delivery condition:BK ,BKW,BKS,GBK,NBK

6. DIN2391-1/EN10305-1

7. GB/T 3639 Cold drawn or cold rolled precision seamless steel tubes

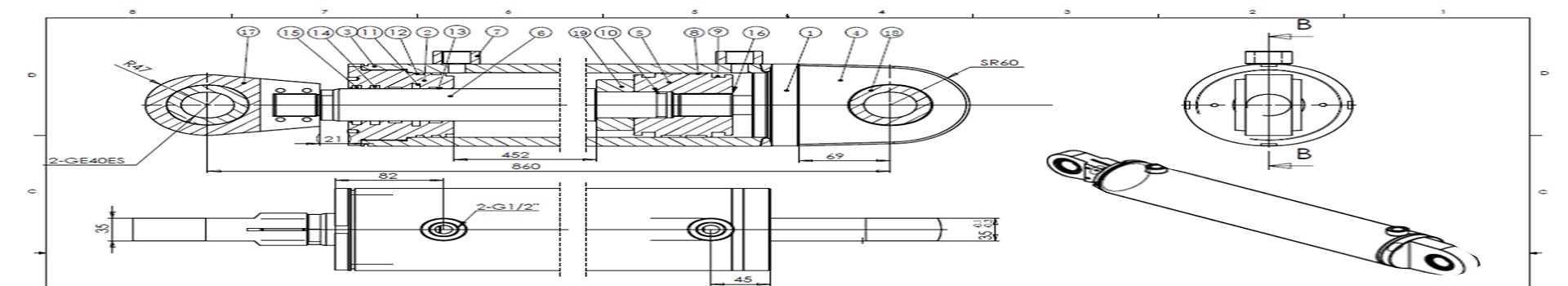

8. GB/T 8713 inside precision seamless tubes for hydraulic pressure and pneumatic services

9. Application: For auto use, for machinery, for oil cylinder tube, auto shock reducer inner cylinder

Other applications:

Widely used in Hydraulic cylinder systems, automobiles, injection molding machine, hydraulic press tube, EVA foam hydraulic machinery, precision hydraulic steel pipe cutting machine, shoe-making machinery, hydraulic equipment, high pressure tubing, hydraulic tubing, card sets of joints, pipe joints, rubber machinery, forging machinery, casting machinery, engineering machinery, automotive high pressure steel pipe concrete pump, sanitation vehicle, car Industry, shipbuilding industry, metal processing, military, diesel engine, internal combustion engine, air compressor, construction machinery, agricultural and forestry machinery, etc

If tubes having the tolerances and are produced according to the technical conditions of deivery as specified in this Standard are to e used as pipelines, then the dimensions specified in DIN 2448 may from time to time be used. These tubes must be ordered according to quality grade C.

DIN 2391 Seamless Precision Steel Tubes Mechanical Properties (Mpa)

|

Grade |

Material |

Tensile Strength |

Remaks |

|

|

Min Yield Point |

Tensile Strength |

|||

|

St30Si |

1.0211 |

- |

400Min |

(STKM11) |

|

- |

355Min |

|||

|

- |

285Min |

|||

|

215 |

295~420 |

|||

|

St30Al |

1.0212 |

- |

400Min |

(STKM11) |

|

- |

355Min |

|||

|

- |

285Min |

|||

|

215 |

295~420 |

|||

|

St35 |

1.0308 |

- |

440Min |

(STC38) |

|

- |

370Min |

|||

|

- |

315Min |

|||

|

235 |

340~470 |

|||

|

St45 |

1.0408 |

- |

540Min |

(STKM13) |

|

- |

470Min |

|||

|

- |

390Min |

|||

|

255 |

440~570 |

|||

|

St52 |

1.0580 |

- |

590Min |

(STKM19) |

|

- |

540Min |

|||

|

- |

490Min |

|||

|

350 |

490~630 |

|||

DIN 2391 Seamless Precision Steel Tubes Chemical composition(%)

|

Grade |

Mfg. Process |

Chemical composition(%) |

|||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Others |

a |

||

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

|

St30Si |

S |

0.10Max |

0.30Max |

0.55Max |

0.040Max |

0.040Max |

- |

- |

- |

- |

a |

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

|

St30A1 |

S |

0.10Max |

0.05Max |

0.55Max |

0.040Max |

0.040Max |

- |

- |

- |

Al deoxydized |

a |

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

|

St35 |

S |

0.17Max |

0.35Max |

0.40Max |

0.050Max |

0.050Max |

- |

- |

- |

- |

a |

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

|

St45 |

S |

0.21Max |

0.35Max |

0.40Max |

0.050Max |

0.050Max |

- |

- |

- |

- |

a |

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

|

St52 |

S |

0.22Max |

0.55Max |

1.60Max |

0.050Max |

0.050Max |

- |

- |

- |

- |

a |

|

b |

|||||||||||

|

c |

|||||||||||

|

d |

|||||||||||

Note: a: Cold-finished/hard b: Cold-finished/soft c: Annealed d: Normalized

|

Delivery status |

Abbreviation |

Description |

|

Cold-finished/hard |

BK (+C) |

No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

|

Cold-finished/soft |

BKW (+LC) |

After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing. |

|

Cold drawn and stress relieved |

BKS(+SR) |

After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere. |

|

Annealed |

GBK (+A) |

After the final cold-forming process the tubes are annealed in a controlled atmosphere. |

|

Normalized |

NBK(+N) |

After the final cold drawing operation the tubes are normalized in a controlled atmosphere. |

|

EN 10305-1 |

Steel Tubes For Precision |

E215,E235,E355 |

20-260mm |

|

EN 10305-4 |

Steel Tubes for precision |

E215,E235,E355 |

20-260mm |

Related standards:

EN 10305-1 E215 E235 E355 Seamless Precision Steel Tube Tubing Tubes

EN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel Tube

GB/T 3639 Cold drawn or cold rolled precision seamless steel tubes

Latest News

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry