Products >> Steel Pipes/Tubes/Chromed Bars >> Precision cold drawn pipe

Precision Seamless Pipe

Precision Seamless Pipe

Precision seamless pipe generally refers to cold drawn or cold rolled precision seamless steel pipe, it is a pipe material with high precision on dimensions tolerance and high quality finish on surface. Precision seamless tube classifications include : precision seamless tube, precision hydraulic seamless tube, cold drawn precision seamless tube, cold rolled precision seamless pipe, high precision seamless pipe, and precision bright seamless tube.

-

DIN2391

-

DIN2445

-

EN10305

-

DIN1629

-

DIN1630

-

GB/T3639

-

GB/T 8713

-

ASTM A179 etc

Cold Drawn Seamless (CDS)

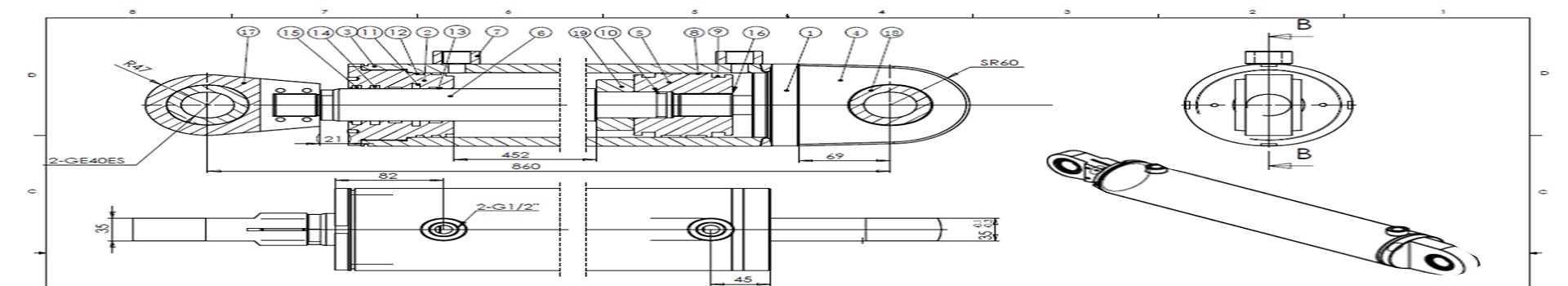

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn steel tube. Produced from hot rolled pipe material. The cold drawing process increases the material's physical properties and offers tighter tolerances compared to hot-rolled products. It is widely used in hydraulics, telescopic cylinders and hydraulic rods, high pressure hydraulic cylinders. Cold Drawn Seamless tubes can be applied in heavy equipment manufacturing such as cranes and garbage trucks, in precision machinery manufacturing, such as auto parts, hydraulic cylinders.

Cold Drawn Seamless Hydraulic Tube

It is typically used on Hydraulic and Pneumatic applications. ed on Hydraulic and Pneumatic applications.

-

DIN2391-1 ST35

-

DIN2391-1 ST37.4

-

DIN2391-1 ST45

-

DIN2391-1 ST52

-

DIN1629 ST37.0

-

DIN1629 ST44.0

-

DIN1629 ST52.0

-

EN10305-1 E215

-

EN10305-1 E235

-

EN10305-1 E355

-

ASTM A519 1010

-

ASTM A519 1020

-

ASTM A519 1025

-

ASTM A519 1045

-

St35 St37.4(E235, 10#) St45(E255, 20#) St52(E355, 16Mn, Q345B)

Conditions on delivery

The tubes are supplied in one of the conditions listed below

|

Conditions |

Symbol |

Explanation |

|

Cold-finished/hard |

BK |

No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

|

Cold-finished/soft |

BKW |

After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

|

Cold finished and stress relieved |

BKS |

After the last cold forming process, the tubes are annealed in a controlled atmosphere, to eliminate the cold processing stress, enables both forming and machining properties to a certain degree. |

|

Annealed |

GBK |

After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

|

Normalized |

NBK |

The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry