Products >> Steel Pipes/Tubes/Chromed Bars >> Seamless steel pipe

ASTM A106 Grade B Seamless Pipe

PIPE SPECIFICATIONS

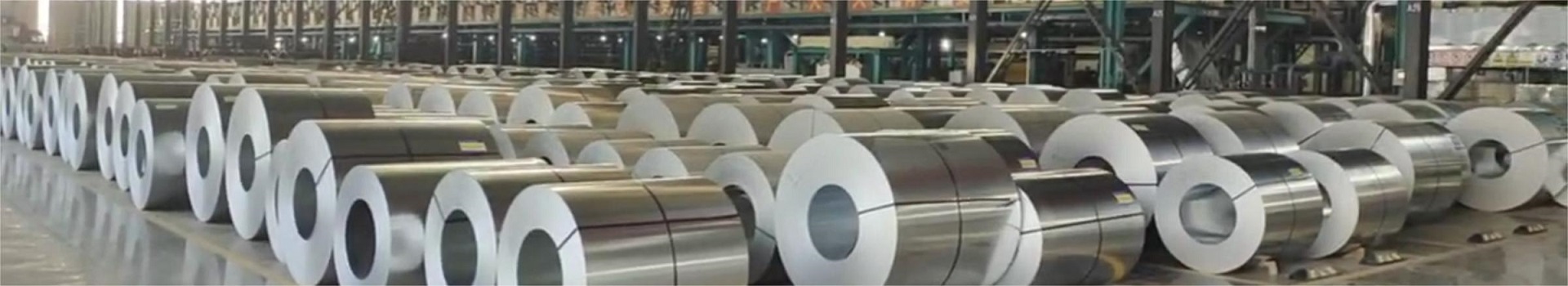

ASTM A106 and ASME SA106 seamless pressure pipe is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

China Piping Products stocks a full range of A/SA106 pipe in:

Grades B and C

OD 1/2 INCH to 25 INCH

Wall thickness for pipe per ASME B36.10 and B36.19

Schedules 10, SCH10S, sch20, SCH STD, sch40, SCH 40S, sch60, sch80, SCH 80S,SCH160, Wall Thickness up to 50mm Thick

Delivery Conditions for Steel Pipes and Tubes

HDG, NBK(+N),GBK(+A),BK(+C),BKW(+LC),BKS(+SR)

Steel pipes can be delivered in various conditions, depending on the requirements of the customer and the intended application of the pipes. Some common delivery conditions for steel pipes include:

1.Black and hot-dipped galvanized: Steel pipes can be delivered in a black or uncoated condition, or they can be hot-dipped galvanized to provide additional protection against corrosion.

2.Cold-rolled:Cold-rolled steel tubes are made from hot-rolled steel tubes that have been processed through a rolling mill at room temperature. This process results in a product that has a smoother surface finish and tighter tolerances than hot-rolled steel tubes.

Cold-rolled steel tubes are commonly used in applications that require a higher level of precision, such as in the automotive, aerospace, and construction industries.

3.Cold-drawn: Steel tubes are made by pulling a hot-rolled or seamless steel tube through a die to reduce its diameter and wall thickness. This process results in a product with a smoother surface finish, tighter dimensional tolerances, and improved mechanical properties compared to hot-rolled or seamless steel tubes.

4.Normalized: Normalized steel pipes are heat-treated to remove any internal stresses and improve their strength and toughness.

5.Annealed: Annealed steel pipes are heat-treated to improve their ductility and toughness, making them more suitable for bending and forming.

6.Quenched and tempered: Quenched and tempered steel pipes are heat-treated to improve their hardness and strength, making them suitable for high-stress applications.

7.Stress relieved: Stress relieved steel pipes are heat-treated to remove any residual stresses that may have developed during manufacturing or processing.

8.Precision: Precision steel pipes are manufactured to very tight tolerances, ensuring that they meet the exact specifications required for the intended application.

Most of the time, these delivery conditions are not mutually exclusive, and a single steel pipe may be delivered in a combination of these conditions.

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry